The smart fortwo tailgate is the first serial E-LFT application (structural part) and first crash resistant LFT component (cover) with completely visible colored grained surface.

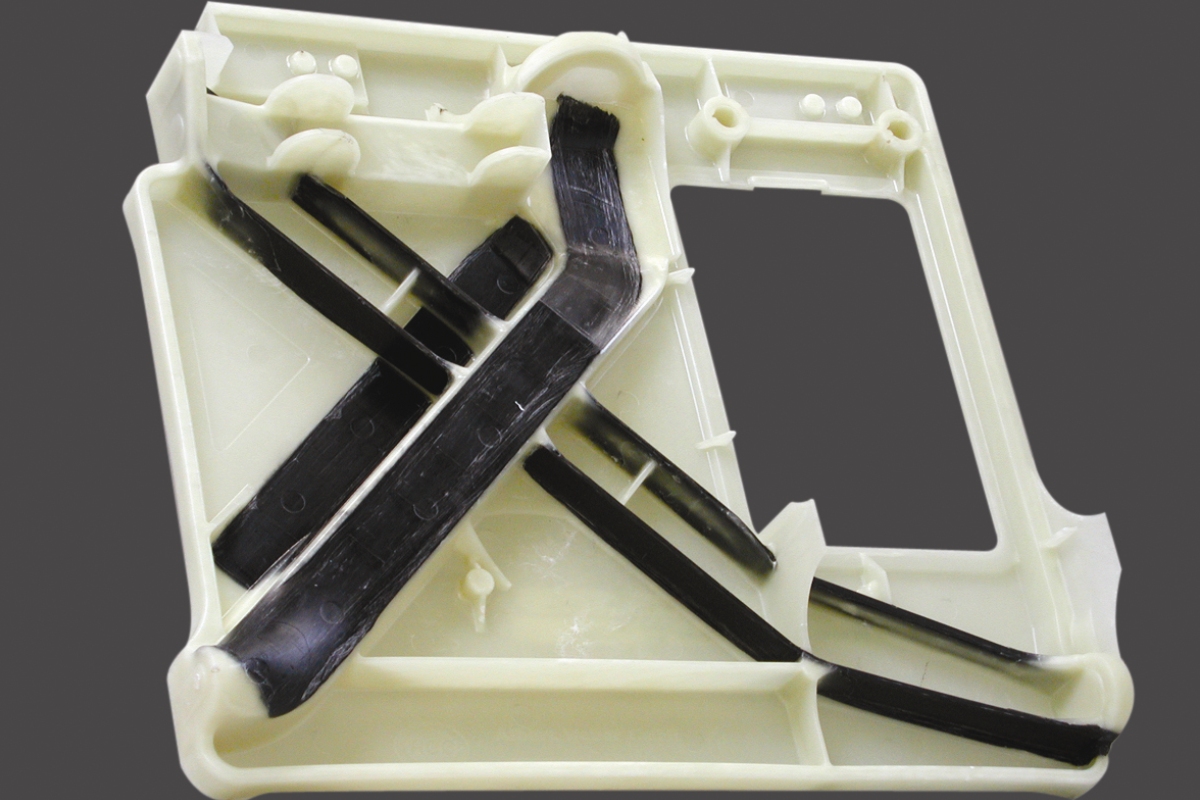

Compared to the previous model, the tailgate of the new smart fortwo complies with much higher rigidity and crashworthiness requirements. The tailgate consists of a structural part with a storage compartment and a hinged inner cover with a completely visible grained surface. Both components comply with crash requirements.

The structural concept was designed and validated by means of numerical simulations and a series of tests. Main emphasis was laid on the behavior of the inner cover in a frontal crash and the increase of the stiffness of the structural part. The inner cover has to retain the two top roof edges (5.2 kg weight) in case of a frontal crash (at 64km/h with the very high time-lag peak typical of compact cars) in order to ensure occupant safety.

To have a minimal investment the same structural concept which can be used for the cabrio and coupé version was elaborated. As consequence of the consequent engineering process, the tailgate fulfils the higher load and stiffness requirements, while a cost reduction of over 10% has been achieved.

Until 2014, WeberFibertech has produced and delivered the components for 800’000 tailgates – at 100% supplier’s reliability.