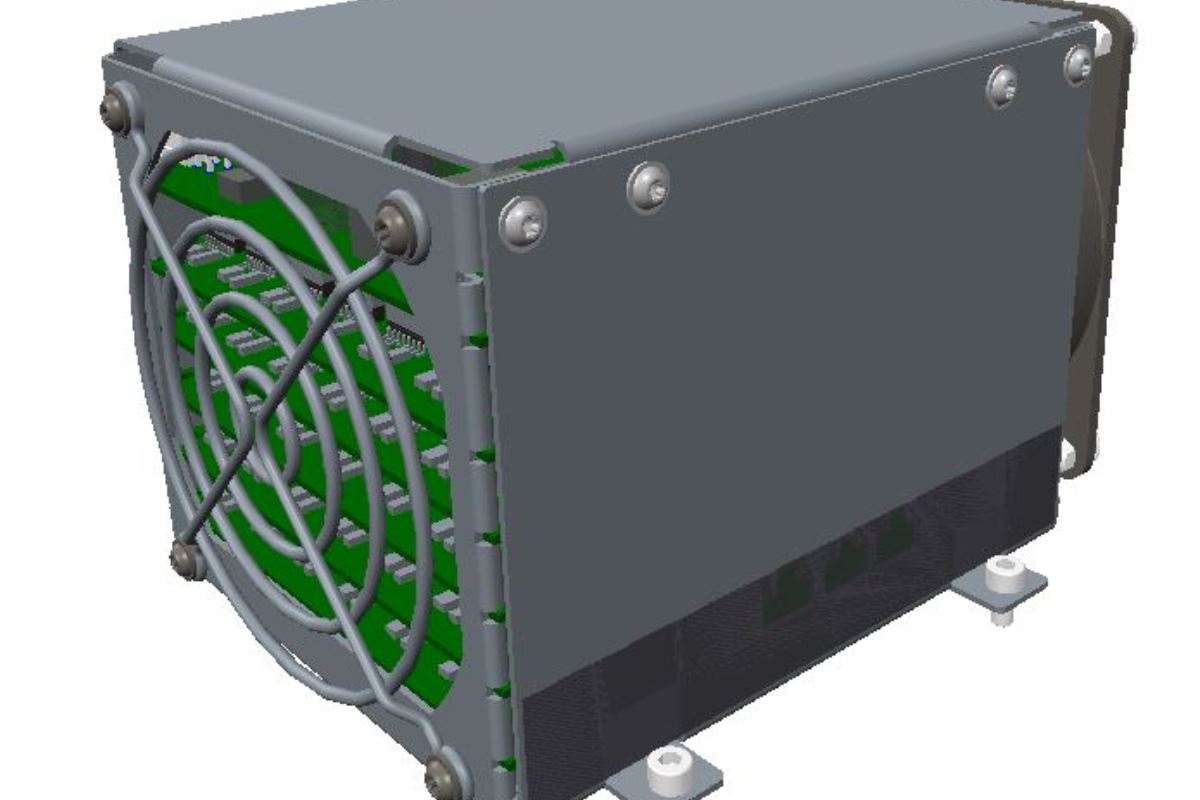

ESORO, the expert in electric drive trains, developed an intelligent Battery Management System (BMS) for the many battery projects they have to deal with. The BMS monitors every single cell of the battery pack and has many temperature sensors. Among many other actual values, the state of charge (SOC), time to empty or to full, and the state of health (SOH) were communicated over CAN (Controller Area Network) bus. Due to its variable size and the parameter ability, the ESORO BMS could be used for almost every Li-Ion battery.

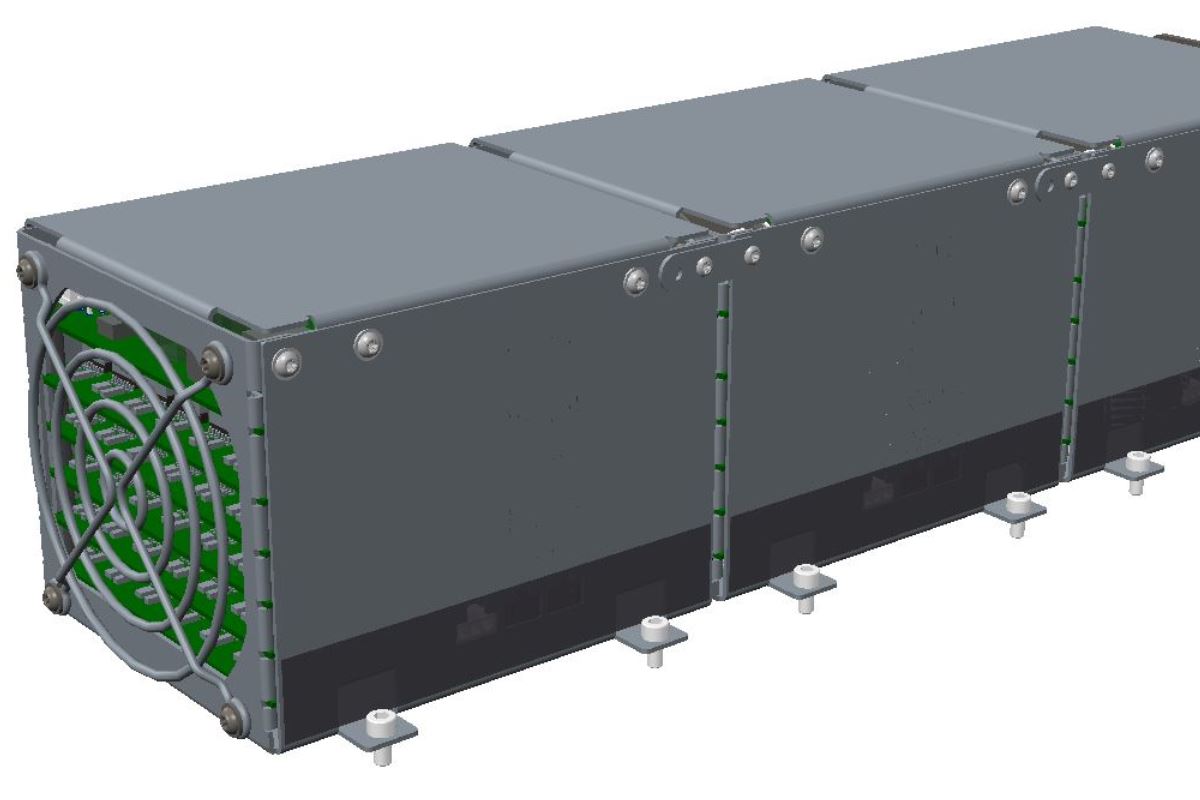

ESORO produces two different designs of the BMS, with different balancing technology to equalize the battery-cells. The active BMS version is made for high capacity cells. The balancing current of more than 4A maximizes the capacity on battery level in a minimal charging time. While active balancing is operating, the power of slightly higher charged battery-cells is rejected to the whole battery pack. This technic helps to reduce the losses to a minimum. The other kind of BMS, the passive version, has a balancing current of 200mA for each cell. Load resistances transform electric energy into heat to gain an efficient balancing. The passive BMS is preferable for low capacity battery-cells.

Every BMS from ESORO is equipped with an internal precharge-unit. With this, the inrush current is held to a minimum while switching the high volt battery to the system. A spark-free connection is guaranteed.