ESORO performed the entire component development process in exemplary manner for a new plastics process (E-LFT) to be developed on a specimen component.

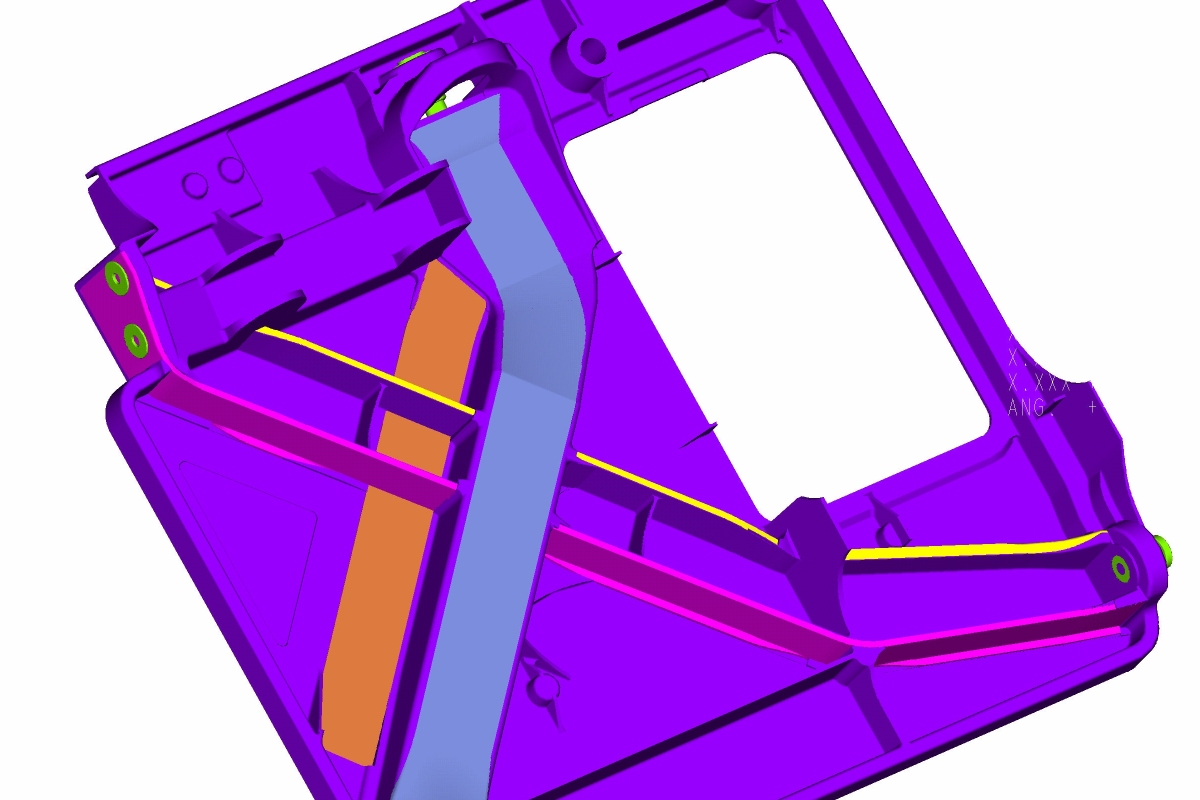

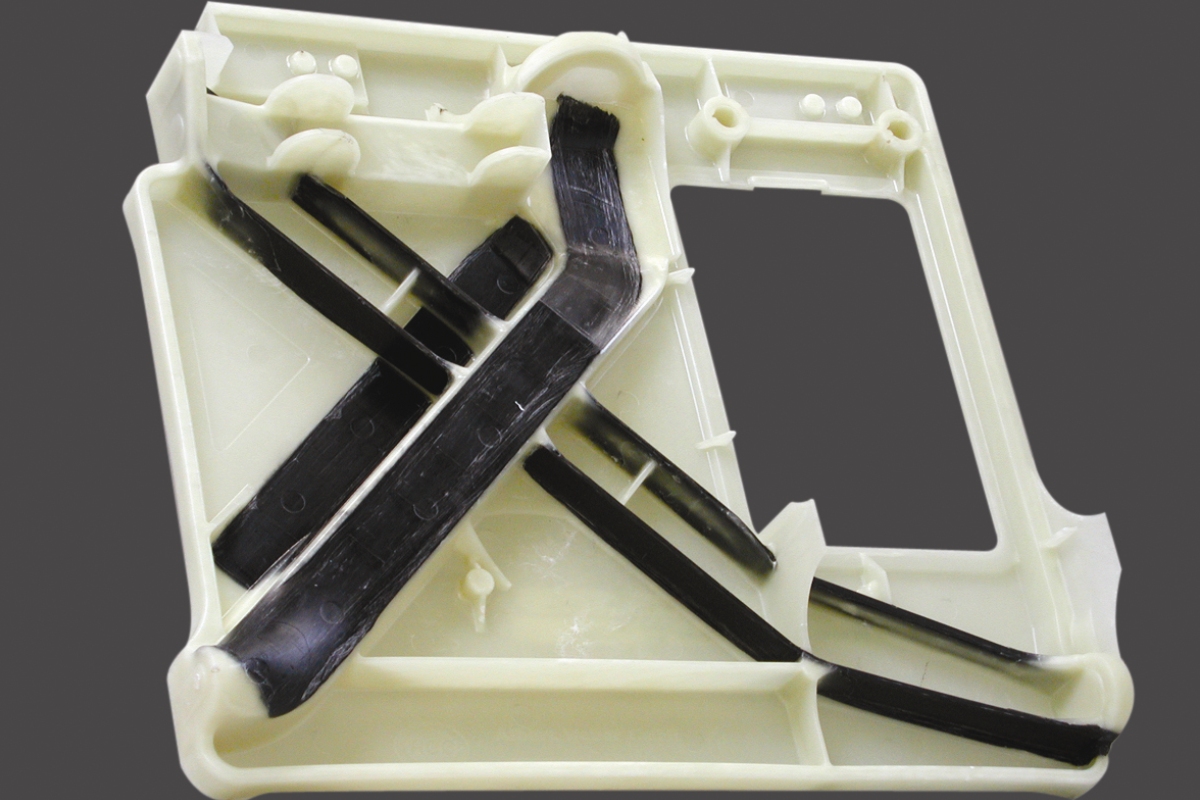

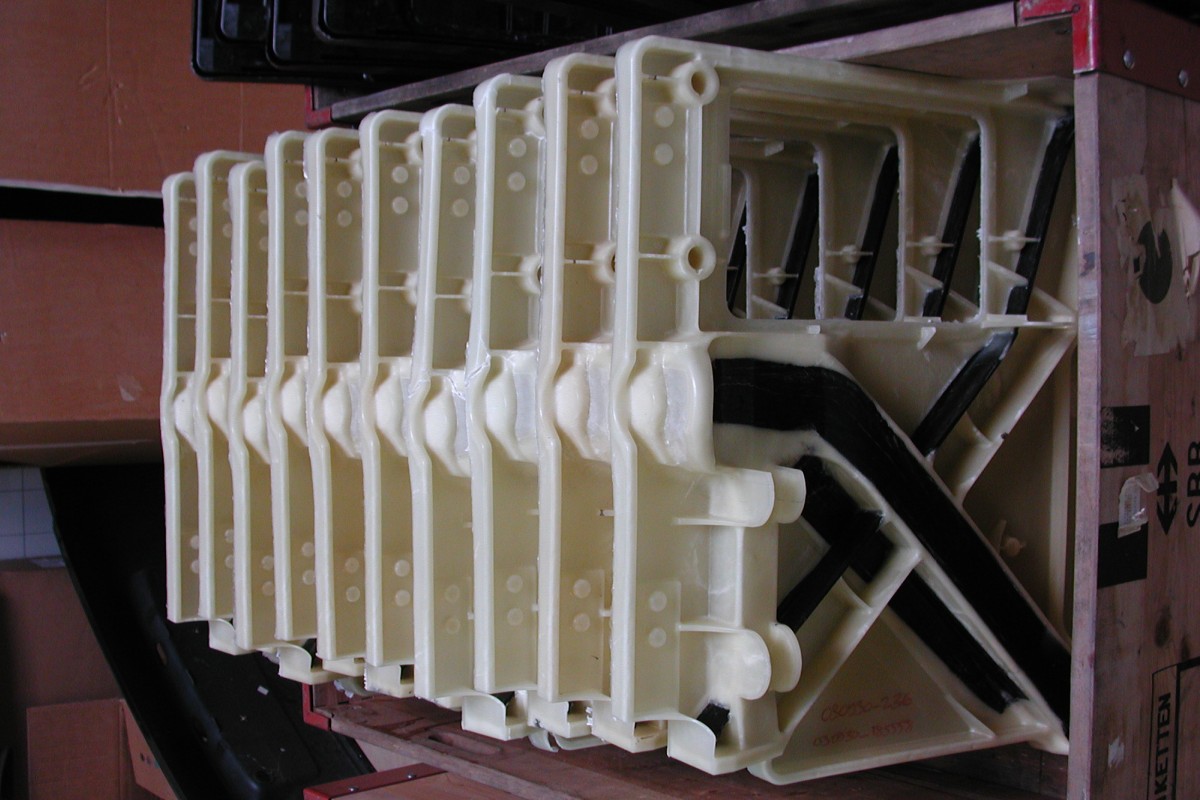

A 2/3 split-folding rear seat backrest with integrated belt and subject to stringent structural requirements was selected as the specimen component. Using this, it was possible, in an exceedingly narrow time window, to successfully map the entire development process. OEM specifications formed the basis for the structure concepts. The design was reviewed constantly with structural analyses for all relevant load cases and process-engineering investigations (e.g. extrusion simulation) provided the input for successful component design. The mould was manufactured directly from 3-D CAD data. The specimen components were produced at our own technical training facility and tested and validated internally in an initial stage, after which they then passed the external crash tests.